MLCC

-

Normal

A general MLCC temporarily charges and remove noise in electronic circuits, and is the most broadly available chip type of capacitor. The product line allows

for realization of various sizes and a wide range of capacitance. It also has the structural capacity to mount chips on a PCB at a high speed.- Application

- Mobile Phone, PC, HDD/SSD Board, Tablet Devices, Display, Game Machine, DC-DC Converter

Wide Selection of Size & Wide Capacitance Range

Excellent DC Bias Characteristics

High Speed Automatic Chip Placement on PCBs

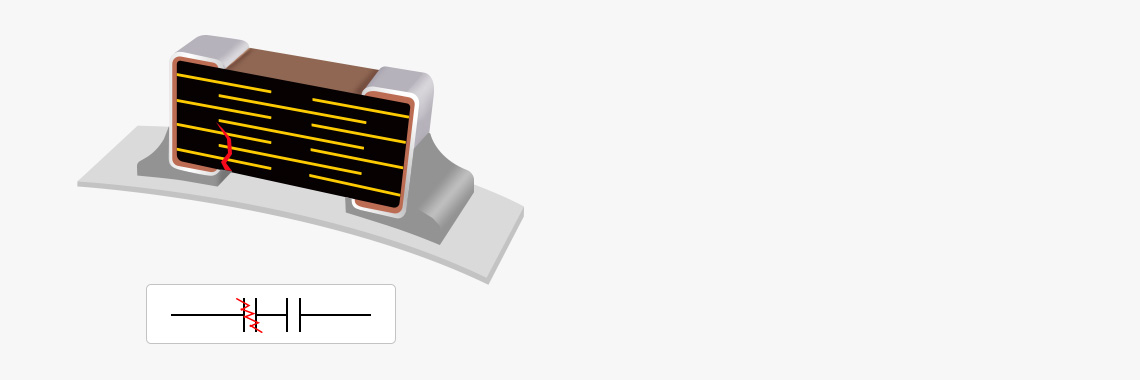

Normal(Epoxy)

- Application

- Automotive Application

ISO 9001 & IATF 16949 Certification

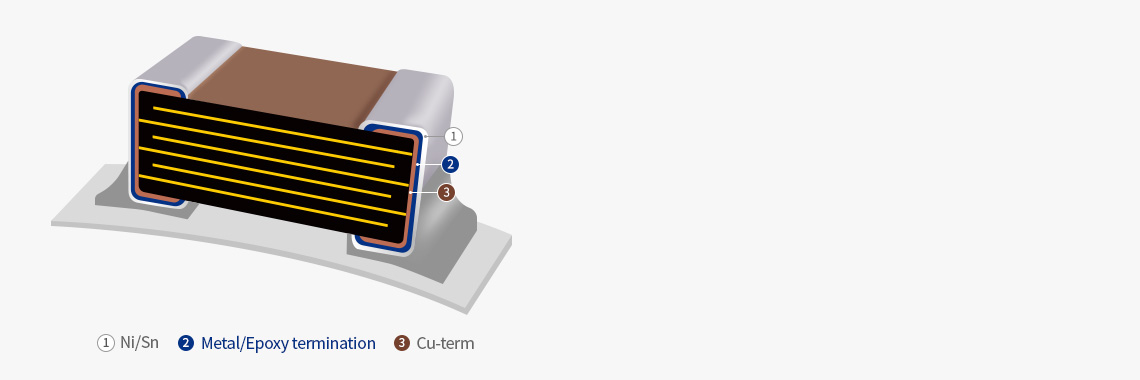

BME and Metal Epoxy Terminations for Class Ⅱ

AEC-Q200 Guaranteed

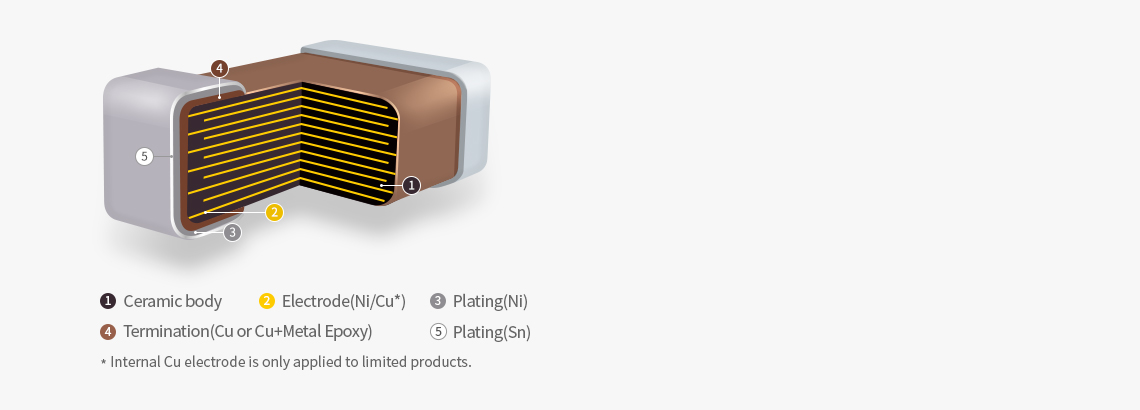

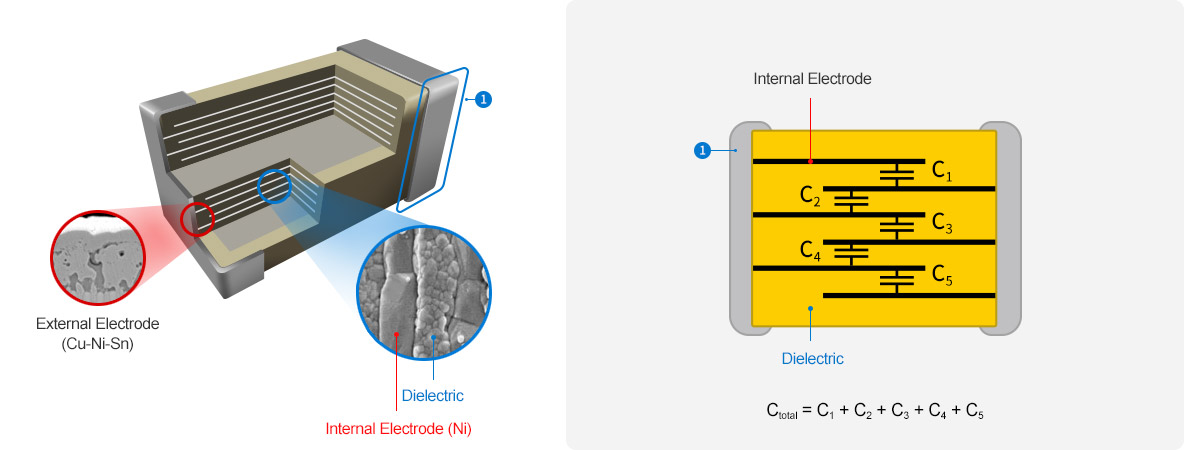

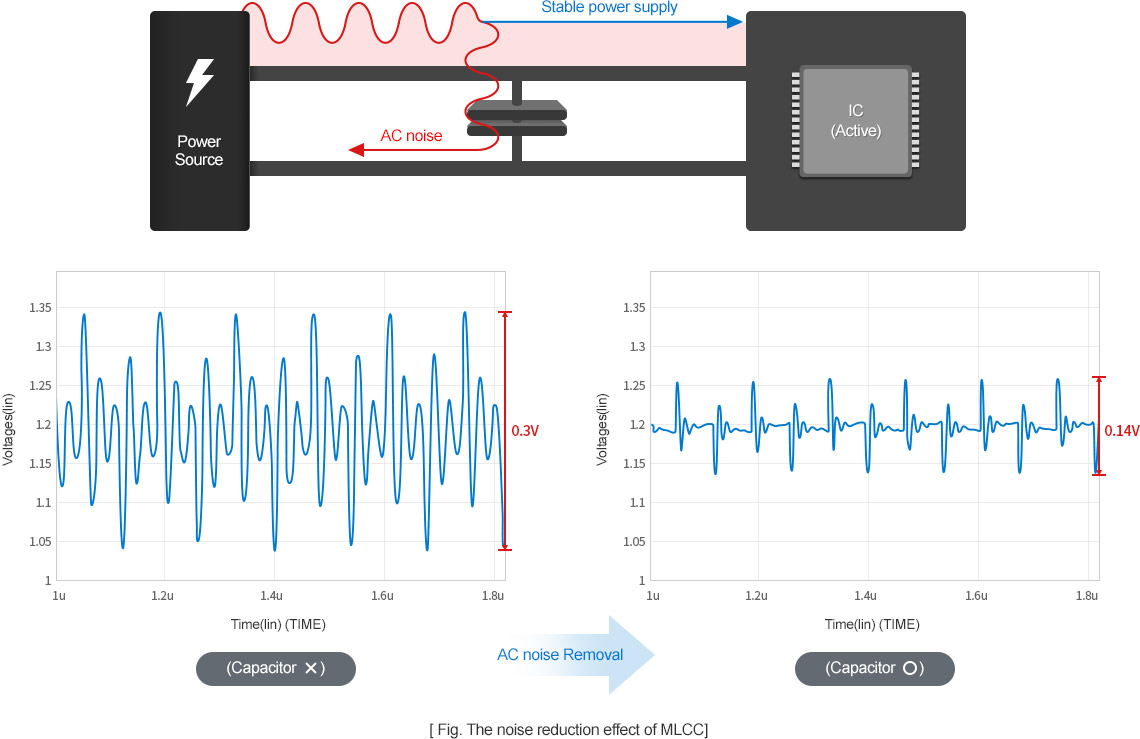

Realizes capacitance by layering dielectrics and internal electrodes

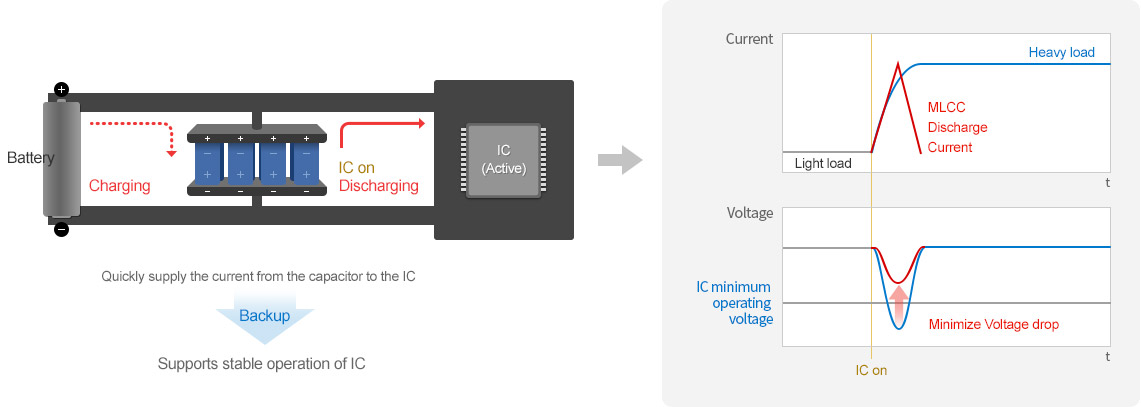

If a large amount of current is needed at the IC instantaneously,

the accumulated current is supplied to the capacitor.

This stabilizes the IC operation by bypassing and removing AC noise from the power line.

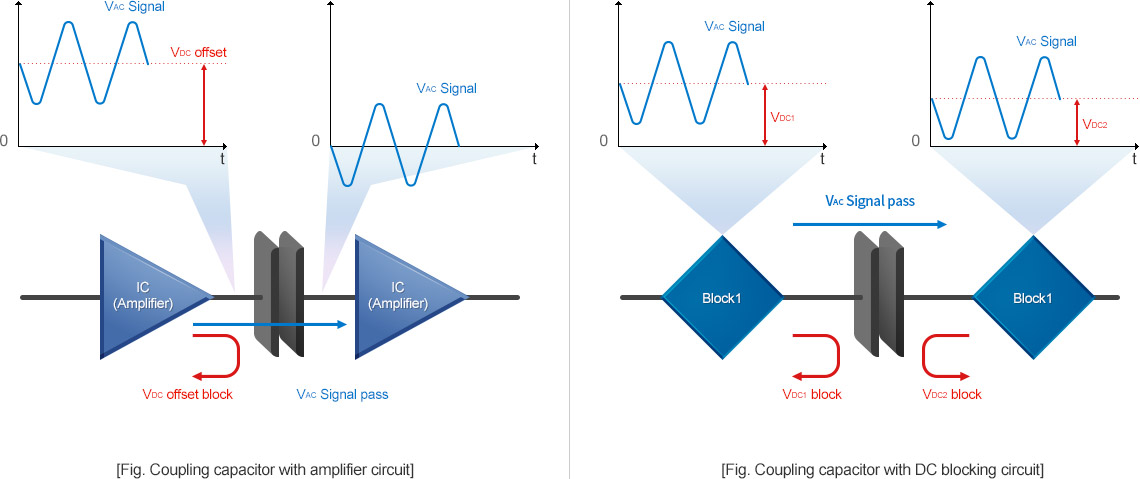

The ability to block DC signals and pass AC signals is widely applied to the separation

or coupling of two circuit blocks.

-

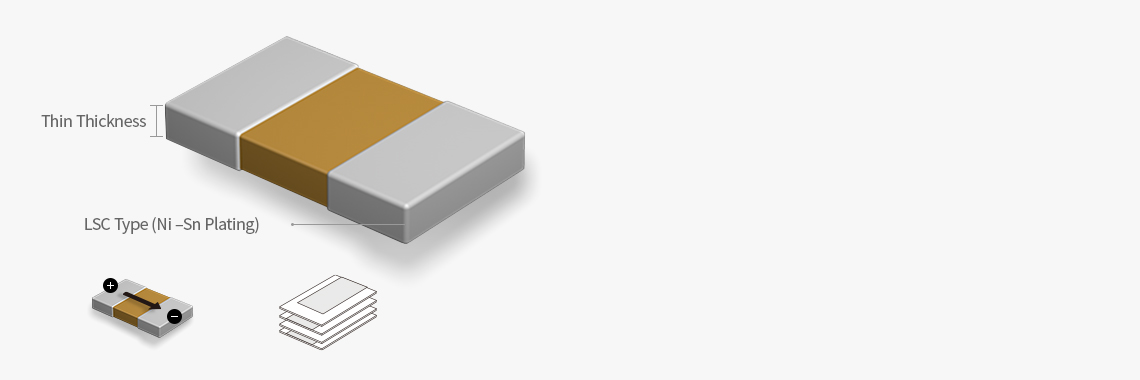

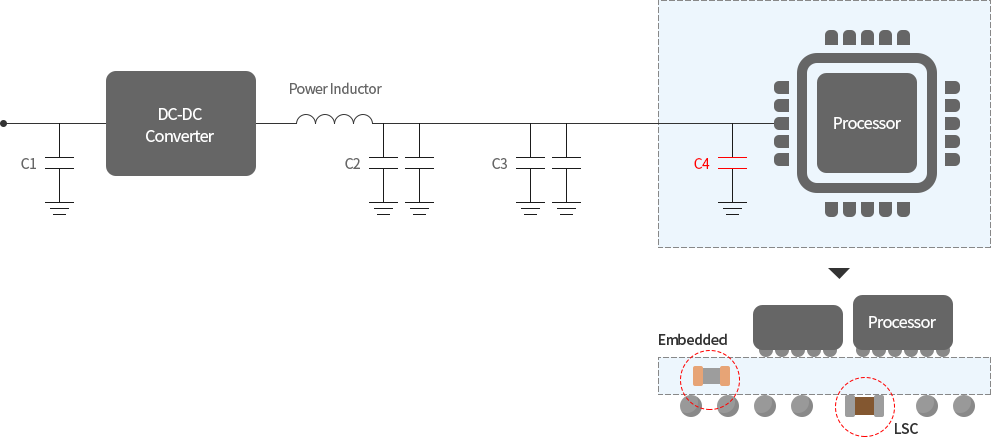

LSC

This can be mounted between the solder balls to deal with thin devices or modules. It can reduce the thickness of the module or be embedded inside the board to secure the mounting area. It can supply current quickly in a stable manner to high-speed AP of mobile devices. In addition it helps remove high-frequency noise, suffering less from external environmental stress.

- Application

- All Demanding Application Such as Mobile Phone, Wearable Devices, IC Package

Appropriate Thickness for The Thin Device

and ModuleRemoving High Frequency Noise

[PDN]

- Thickness of SubstrateThickness of Embedded capacitor

- Height of Solder ballThickness of LSC

-

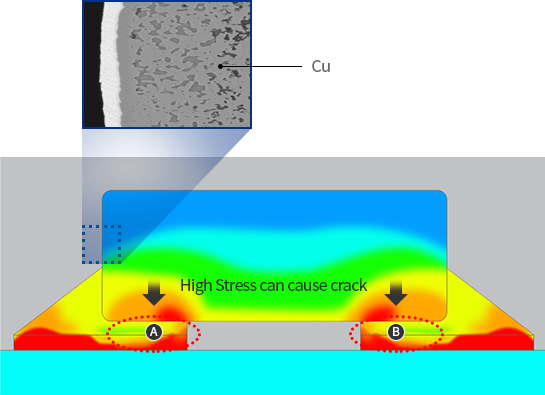

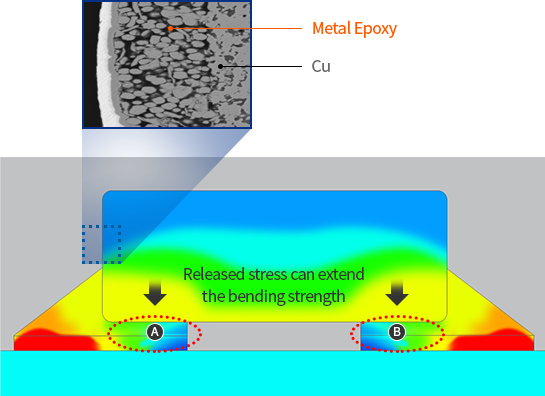

High Bending Strength(General)

The thermal/mechanical stress on the chip can be reduced by the ductile properties of soft termination. It is also resistant to stress caused by board bending.

- Application

- All Application (Smart Phone, PC, HDD/SSD Board, Tablet, Display, Etc), Power(SMPS, DC-DC converter), Industrial Application

Reduction External Thermal/

Mechanical Stress on The ChipExcellent Bending Strength

[ Cu only Termination ]

[Soft Termination]

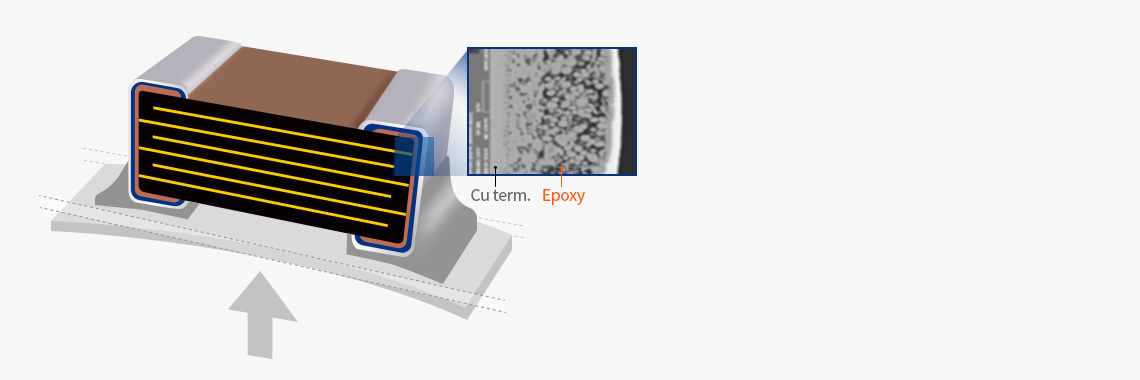

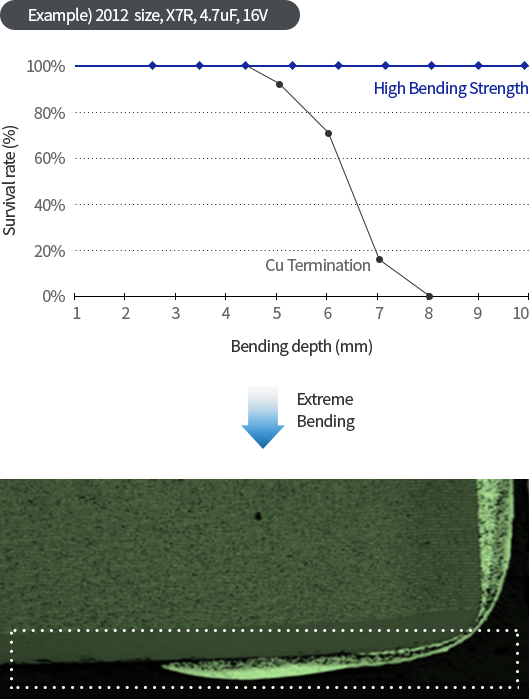

High Bending Strength(High Bending Strength)

This product applies stress-management technology against external deformation so as to prevent MLCC defects from taking place when mechanical/ thermal deformation of PCB occurs. With greater durability than existing products, it can be used in applications requiring safety.

- Application

- Automotive Application

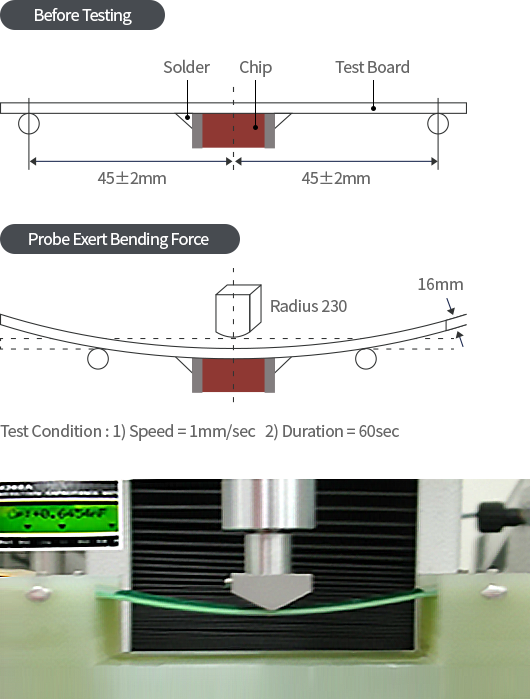

- Bending Crack Prevention

- Application of conductive Epoxy material technology that can absorb deformation stress to prevent bending cracks caused by PCB deformation

- 5mm Bending Guarantee

- No bending cracks guaranteed for Board Flex 5mm variants

Board Flex Test System

Board Flex Test Result

[DPA results after bending test]

Part Number

Part Number 테이블 Grade Automotive Part Number CL□□□□□□□□□□PJ□ Board Flex 5 mm -

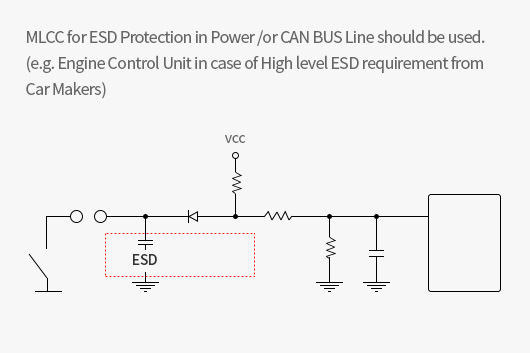

ESD Protection

Specialized for use in protecting circuits from ESD, this component guarantees a higher level of ESD than typical MLCC products.

It meets the IEC 61000-4-2 standard.- Application

- Automotive Application

ESD Testing According to The IEC

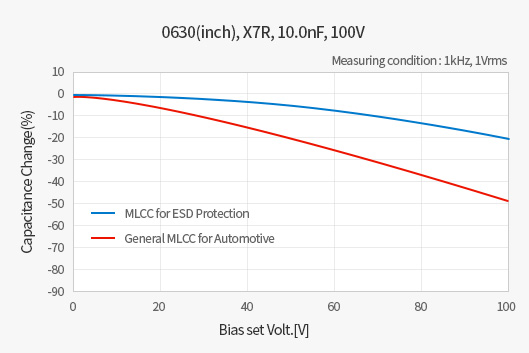

61000-4-2 StandardImproved DC Bias Characteristics Compared

to General MLCC

Part Number

Part Number 테이블 Grade Automotive Part Number CL□□□□□□□□□□PE□ Application ESD Protection Features & Benefits

- PE series meet IEC 61000-4-2 standard (ESD immunity (150pF, 330Ω)

- Improved ESD performance of Class II

- : Enhanced Breakdown Voltage & DC-Bias stability

Background

Improved DC-bias Stability (Class II)

-

Fail Safe(Soft Termination 5mm)

Designed to prevent circuit malfunction in the case of an internal shunt caused by a crack occurs in an MLCC product. This also guarantees 5mm bending and

prevents defects caused by PCB deformation. This product has the highest degree of safety among all MLCCs.- Application

- Automotive Application

- Series Design

- Designed to operate like two MLCCs in a series

- Even if a defect such as a crack occurs on one side,

the circuit can be protected on the other side

- 5mm Bending Guarantee

- Guarantee No Bending Cracks for Board Flex 5mm Variants

Part Number

Part Number table Grade Automotive Part Number CL□□□□□□□□□XPJ□ Board Flex 5 mm Design Series Structure

Background

Requirements for MLCC from car makers:

- Conventional MLCCs should be arranged in series

- Using a multilayer ceramic capacitor with series design

- Using an Open Mode capacitor

Features & Benefits

- Fail Safe function with a series structure design & Metal-epoxy termination

- 5 mm bending strength

-

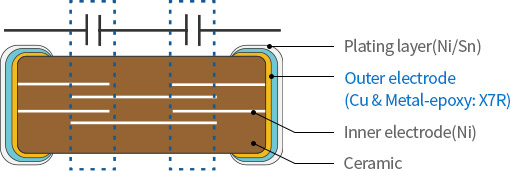

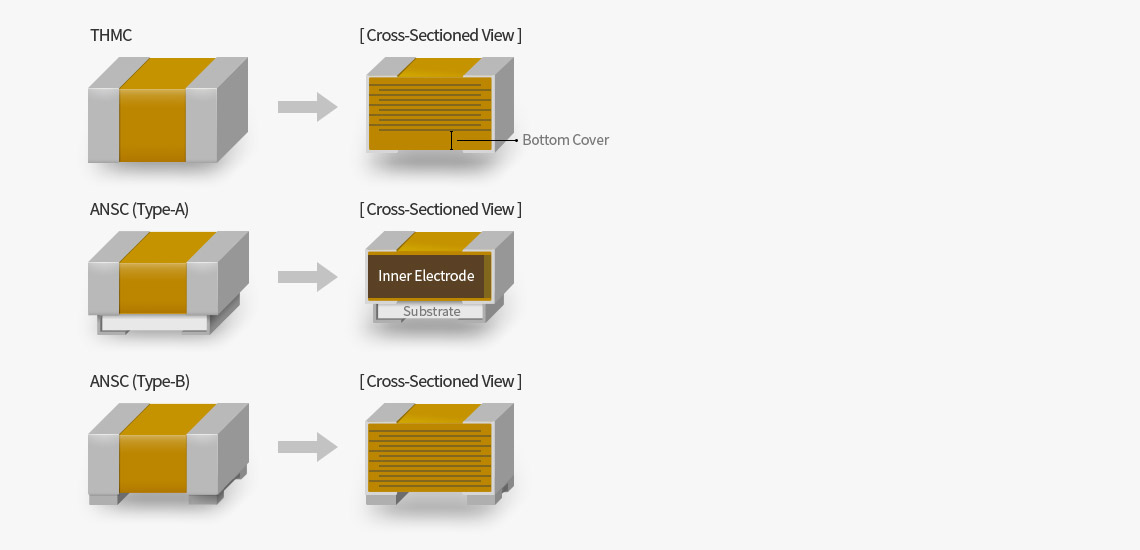

Low Acoustic Noise

MLCC tremors can occur due to piezoelectric phenomena in electronic devices. These tremors are transmitted to the substrate, causing the substrate to tremble,

producing audible noise (20Hz~20kHz). Low Acoustic Noise products are a solution that can effectively reduce this noise.- Application

- PAM(GSM, TD-SCDMA, TDD-LTE), PMIC, DC-DC Converter

- Reducing Audible Noise

- A solution to reduce the noise of mechanical vibrations

caused by piezoelectric properties

- Pin to Pin Solution

- A solution to establish noise reduction measures

by replacing existing products immediately

[Mechanism of Acoustic Noise Generation]

-

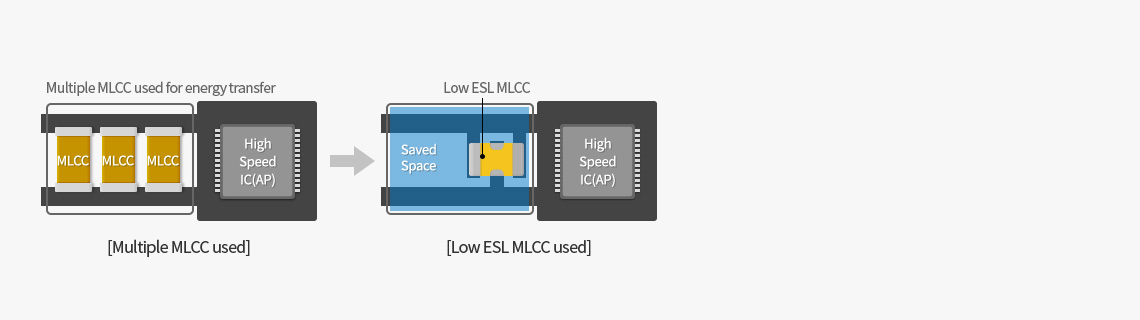

Low ESL

MLCCs with low equivalent series inductance (ESL) can be used in circuits with limited mounting area, as a small quantity of such MLCCs can sufficiently replace high-speed IC MLCCs.

- Application

- All Demanding Application Such as Mobile Phone, Wearable Devices, IC Package, PC

Faster Energy Transfer

Saving Space by One Chip

Space Saving Comparison of Low ESL Capacitors

Space Saving Comparison of Low ESL Capacitors table Low ESL Capacitor ESL value Replacement of MLCCs Space Saving LICC 85 pH 3 pcs ~ 15% 3T Cap 65 pH 4 pcs ~ 36% VLC 45 pH 6 pcs ~ 60% * Low ESL Capacitor: 1005 size / MLCC: 0603 size

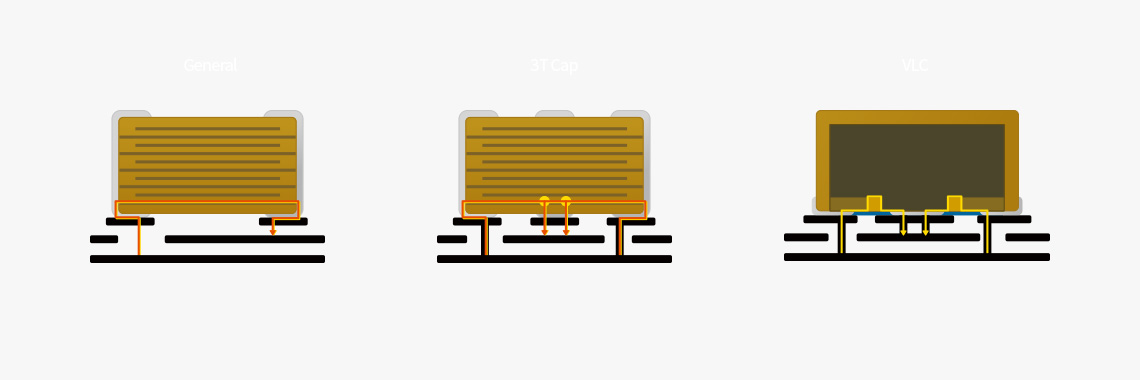

ESL Comparison

- General

- 3T Cap

- VLC

-

- Single Current Loop

-

- Double Current Loop

- Small Loop Area

-

- Double Current Loop

- Very Small Loop Area

-

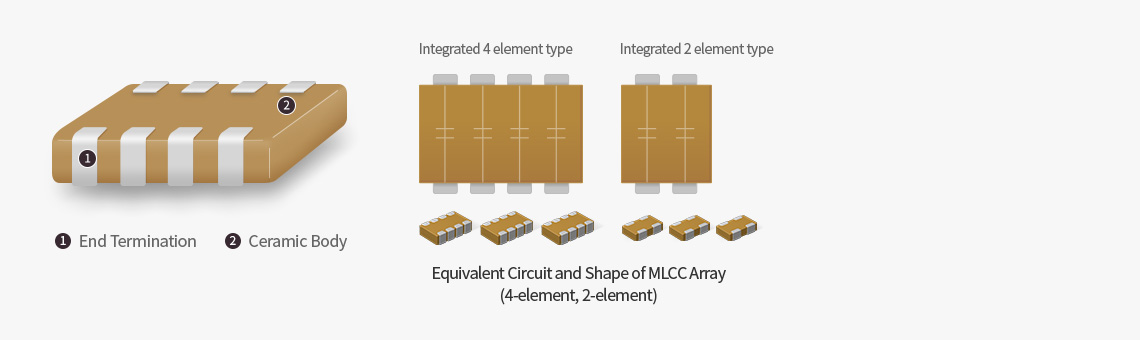

Array

As various electronic products such as portable devices have gotten smaller, several chips have been unified in order to secure mounting space.

This reduces the cost of mounting and the ripple voltage.- Application

- All Application(Mobile Phone, PC, HDD/SSD Board, Tablet Devices, Display etc.), High Performance & Multi Function

High Performance Product for

the Mounting Area Reduction

Lineup