Power Inductor

-

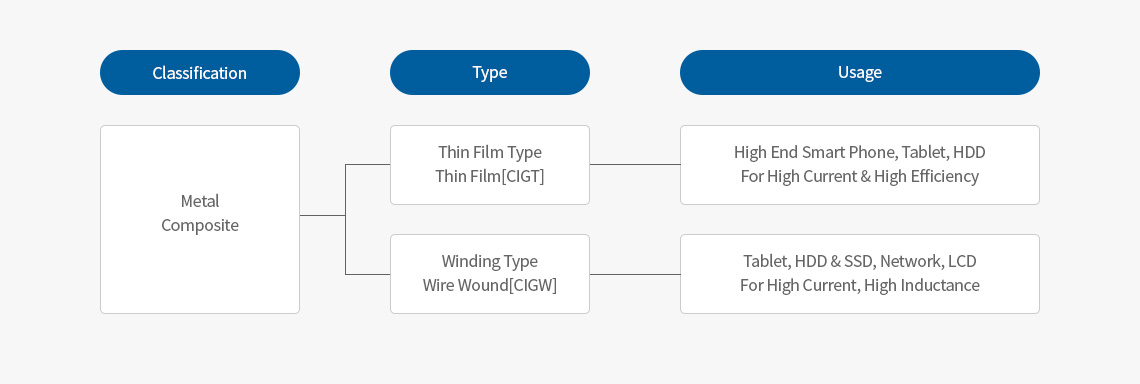

Metal Composite

Depending on the body materials, power inductors are divided into ferrite inductors and metal composite inductors.

The metal composite inductors have a high rated current and are very efficient.- Application

- Smart Phones, DC-DC Converters for DSC, DVC, PDA, and Others

Characteristics of Metal Magnet Thin Film Type

Depending on the body materials, power inductors are divided into ferrite inductors and metal composite inductors.

The metal composite inductors have a high rated current and are very efficient.- 1. High Efficiency

- Low Loss Material

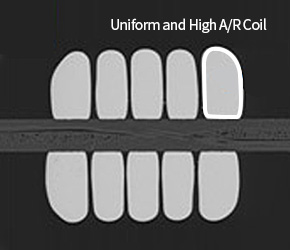

- 2. Low DC Resistance

- High Aspect Ratio Copper Plating

-

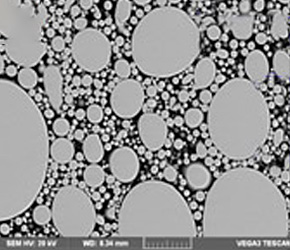

Body Material

-

Shape of Internal Electrodes

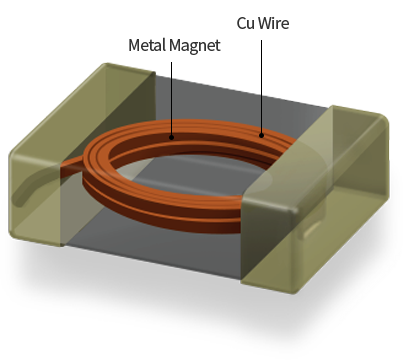

Characteristics of Metal Magnet Winding Type

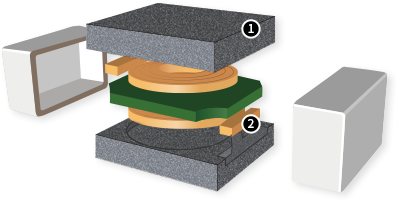

Metal magnet winding-type inductors have high-efficiency and high-current (DC-bias) characteristics due to their optimal body material composition and coil.

These inductors are recognized for their high capacity (4.7 μH).

[Winding-Type Structure]

-

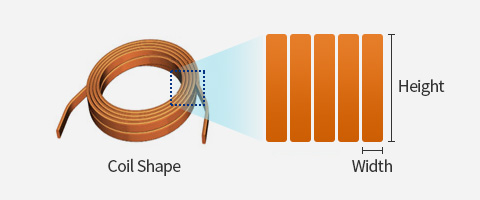

Low DC Resistance

-

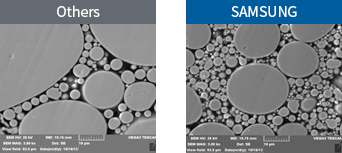

Uniform Packing Technology

[Body Packing Status Comparison]

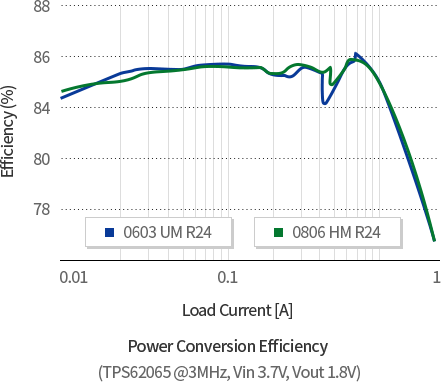

Superb Efficiency Characteristics

If the power inductor efficiency is low, battery consumption increases. Efficiency test results show that power inductors are superior to ferrite winding-type inductors in terms of efficiency. Samsung has continuously developed and launched metal magnet power inductors with improved efficiency.

Efficiency

테이블 0806 HM 0603 UM Size(mm) 0806(2016) 0603(1608) Height 1.0mm 1.0mm Norminal 0.24 uH 0.24 uH DC Resistance Typ 17mΩ 28mΩ Rated Current

△L=30% Typ5.3A 3.8A Rated Current

△T=40℃ Typ4.5A 3.3A Switching - 3~9.6MHz Remark MP Sample Available Winding Type

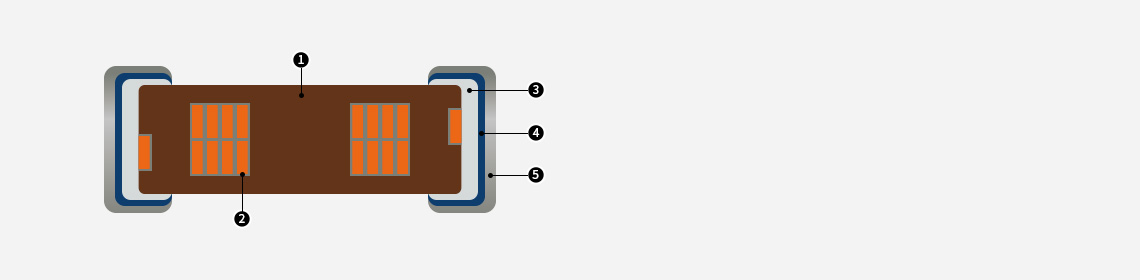

Winding-type inductors are made by winding coils in “α” shape and the surrounding magnet around them.

Chip Body

Internal Electrode

External Electrode

Plating

Plating

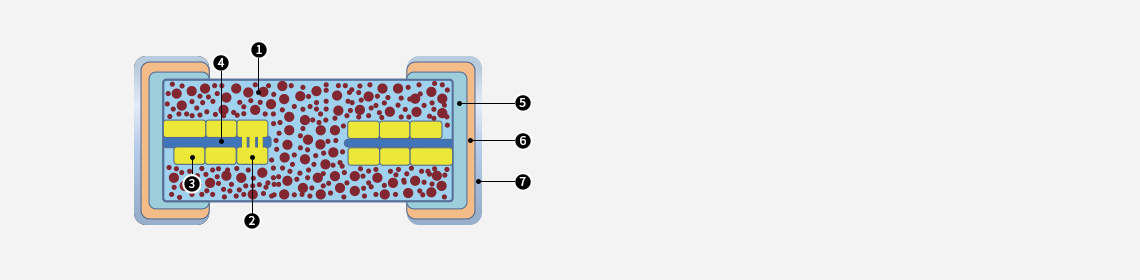

Thin Film Type

Thin film–type inductors are made by plating coils on substrates and surrounding them with magnets.

Chip Body

Internal Electrode

Insulation Layer

Substrate

External Electrode

Plating

Plating

Lineup